We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

What is a Cleanroom?

Your guide to a successful cleanroom project

The ISO 14644 standard’s definition of a cleanroom is a cleanroom is a “room within which the number concentration of airborne particles is controlled and classified, and which is designed, constructed and operated in a manner to control the introduction, generation and retention of particles inside the room.

Cleanrooms are essential for industries requiring controlled environments, e.g. the manufacture of pharmaceuticals, semiconductors, medical devices and aerospace products. A cleanroom’s purpose is to prevent contamination, ensuring product quality and safety, in the Pharmaceutical environment patient safety is critical.

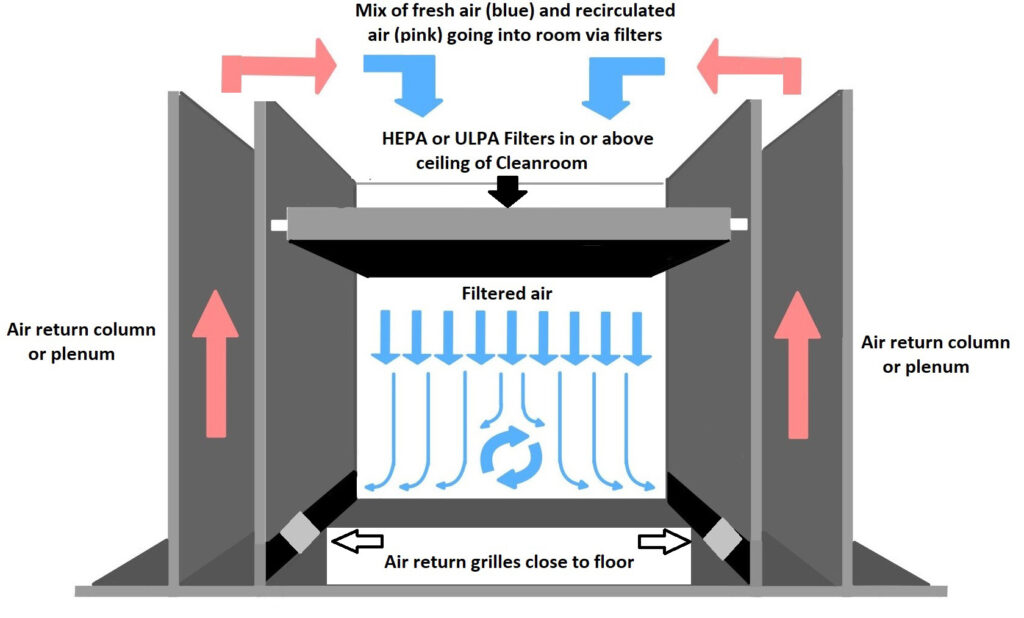

To meet the requirement for controlling the concentration of airborne particles, a cleanroom is supplied with air which is filtered through HEPA (High Efficiency Particulate Air) or ULPA (Ultra Low Penetration Air) filters. The filtered air dilutes and removes particles from the room and is also used to pressurize the area.

Shown below is a very simple layout of a recirculating cleanroom. Pre HEPA or ULPA filtration the air would typically be preconditioned via an air handling unit (AHU), this may also include prefilter steps.

Dependent on your requirements, Cleanrooms may also be Single Pass, where all air entering the room is preconditioned fresh air and this is passed out to the surrounding environment, having undergone a filtration process where necessary.

Temperature and Humidity in the cleanroom may be controlled by HVAC or independent heating/cooling units and humidifiers/dehumidifiers as required.

Cleanrooms must be built with materials that do not generate particles and staff working in the cleanroom must wear garments that minimize the dispersion of particles. Cleanroom garments must protect the environment from the microorganisms that can be generated by people.

Who are the Key Stakeholders in a Cleanroom Project?

Designing, constructing and validating a cleanroom requires collaboration between multiple stakeholders, each playing a crucial role in the process. Whether you are exploring cleanrooms for the first time or preparing for a new project, that requires and additional cleanroom, understanding this diverse group of key players and their contributions is essential.

-

End Users

The individuals in an organization who will operate the cleanroom are central to the process, this group may include production, quality and engineering staff. End users provide essential input about:

- Cleanliness requirements (e.g. ISO Class 5, ISO Class 7, GMP Grade C).

- Workflow and operational needs.

- Specific equipment or processes that will be included in the cleanroom.

- End user’s understanding and insights into their process guides the overall design to ensure the cleanroom meets industry, operational and where applicable, regulatory, standards.

-

Design Engineers

Design engineers are responsible for designing the physical structure and systems of the cleanroom, including architectural and mechanical and electrical systems. Design engineer’s expertise ensures:

- Correct layout and space utilization.

- Integration of HVAC systems, lighting and utilities.

- Compliance with industry and/or regulatory standards, e.g. ISO 14644 or GMP.

- Design Engineers play a crucial role in turning the end user’s vision into a functional design.

-

Cleanroom Suppliers and Contractors

Cleanroom suppliers and Contractors specialise in cleanrooms and bring the design to life. They use industry-specific materials, such as:

- Suitable walls and ceiling systems.

- Seamless, chemical-resistant flooring.

- HEPA filtration systems.

Their products and skills, together with supporting technical information and/or commissioning reports, ensure the construction meets both cleanliness standards, operational demands and where applicable, regulatory requirements.

-

Compliance and Quality Experts

These professionals are responsible for ensuring the cleanroom meets regulatory and industry standards. They focus on:

- An in-depth understanding of the regulatory standards in the country where the cleanroom will be sited.

- Regulatory review of the User Requirement Specification (URS) for the cleanroom.

- Review of initial design to ensure the proposed layout will meet the process and regulatory requirements.

- Oversight of qualification/validation documentation and processes.

- Ensuring conditions in the cleanroom are compliant, e.g. air quality, airflow, and pressure differentials.

- Identifying and addressing potential risks, deviations and nonconformances.

-

Project Managers

Project managers oversee the entire process, acting as a bridge between the stakeholders. Their role includes:

- Managing budgets and timelines.

- Coordinating communication between teams.

- Addressing challenges to keep the project on track and within budget.

Key Considerations

When designing and constructing a cleanroom, all stakeholders must align on the following factors:

-

Regulatory Standards

Cleanrooms are classified based on the level of cleanliness required. For example:

- ISO Class 5: Ideal for critical environments like semiconductor manufacturing.

- GMP Grade C: Common in non-sterile pharmaceutical production, e.g. manufacture of oral capsules.

- Understanding and adhering to these regulatory classifications and standards is essential.

-

Workflow Design

The cleanroom layout must balance productivity with contamination control and meeting any regulatory requirement. For example:

- Unidirectional airflow to minimise particulate contamination.

- Segregated areas for personnel and materials.

- Separate routes out of the cleanroom for finished product and waste.

-

Material Selection

Cleanroom materials must be durable, easy to clean, and resistant to contamination and to cleaning agents and disinfectants. Common options for a ISO Class 7 cleanroom may include:

- A cleanroom wall panel and ceiling system.

- Seamless vinyl or resin flooring.

-

Budget and Timeline Management

Stakeholders must prioritize open communication to prevent costly delays and ensure realistic expectations.

Common Challenges and Solutions

Misaligned Expectations

Frequent project meetings and clear documentation help keep everyone on the same page.

Regulatory Complexity

Ensure compliance experts are engaged early to navigate regulations and avoid costly rework.

Integration of Technology

Early collaboration with equipment suppliers ensures seamless integration of systems such as an Environmental Monitoring System (EMS).

Cleanroom design and construction is a highly collaborative process involving multiple stakeholders, each bringing their unique expertise to the table. From design engineers to end users, project managers and compliance experts, each role is vital to creating a cleanroom that meets operational and regulatory standards.

By fostering open communication and understanding the responsibilities of each stakeholder, you can ensure a smoother process and a successful outcome. Whether you’re just starting or looking to refine your approach, collaboration is the key to your cleanroom success.